Post 13:

Test demo with light

Post 12:

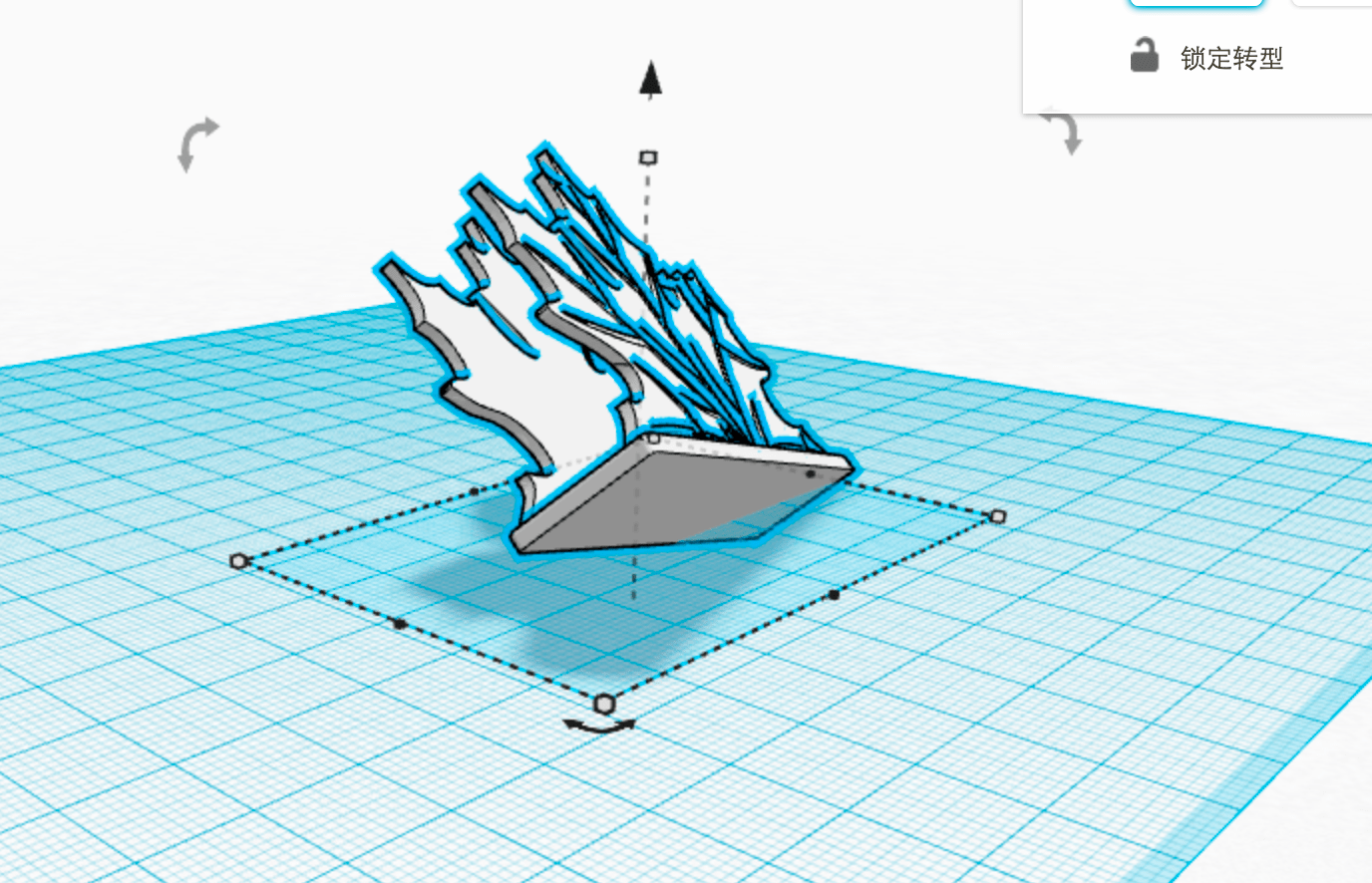

Final model

Post 11:

PDF of final project

Post 10:

the digitization of traditional practices

Chinese Embroidery Art

Embroidery is a Chinese traditional art, it has more than 2000 years history since ancient China. It is very beautiful and because of it’s a kind of hand making art so the value of embroidery is not cheap. However, with the digitizing developing, the labor cost of the embroidery making reduce a lot. The price of the machine made embroidery is even 10 times lower than the hand making embroidery. The mass production and repeat production become possible because of the digitizing.

Embroidery machine working example

Post 9:

Reflecting on Phase 1 and 2

During the P1 and P2, I have been familiar with using 3D printer and using autocad to build the 3D model, and at the same time I learn more about the materials for the 3D printing. I also visited to my friends 3D printing center which is located near Green point Ave in Brooklyn and saw a lots of interesting 3D print product.

For the final project, I might combine the 3D printing(for the body) and laser cut stuff(as decoration) to build a lampshade.

.

How to make a lampshade

————————————————————————

Post 8:

Final Article

https://drive.google.com/open?id=0B3_a-h5fTMmMRk12cnNhVHI0bHM

Post 7:

Tianyu Ren

Digital fabrication

Arlene Ducao

3D printing is the future?

Some science-fiction scene will soon become a reality: you may design according to their preferences to create every piece of furniture at home; you can manufacture your unique toy designed for kids. In 2012, the world’s first 3D printing the studio opened in Japan, took 15 minutes to scan the body shape of the computer, 3D color printer can print out the 3D portrait.

Chris Anderson always gives people surprise. From “The Long Tail” to “Free”, then this “Makers”, I can see his understanding of the Internet is constantly changing, and his theory is more and more mature. From the real to the virtual, and then back to virtual from reality. By the technology, wealth, talent support, the Internet is changing the whole world in constant evolution, and a technological revolution. So, what the future of the world is like?

Anderson gives the answer in his book – who believes the manufacturing, who could have the success at last. Anderson’s logic is very simple when the Internet completes the virtualization of reality, the business development of the internet will come to an end, it must and it will start to develop a lot of other business. More and more internet companies will choose to build a connection on their online and offline products. So we can see Google driver, Google Glass, and other products. But what the more important thing is, compared with traditional manufacturing, the Internet industry is much more powerful and efficient. Examples cited in the book of Citibank: According to Oxford Economics data Citibank institutions, broadly defined digital economy gains of about $ 20 trillion while the total outside of the network economy, according to the same standard estimate of 130 trillions of dollars. The next ten years of the Internet only could find their future by more focus on manufacturing.

To this end, Anderson went to Manchester Britain’s first industrial revolution clues and try to find future proof (the chapter title is “The History of the Future”) in the past. Then he held up “the long tail” theory which made him famous, the long-tailed line extending to the line, extended from the long tail of virtual entities to the long tail, he further illustrated with the representatives of large industrial-scale production technology gradually fading, consumers need the more unique, and more personalized products.

With the market right now, how can we meet consumers’ demand? Here the core of this book Anderson –How to give consumers unique and personalized products. Here three kinds of ideas:

1.Digital desktop tools (such as 3D printing technology) design products

2.Share design results in the open source community, and do more cooperate with other people.

3.Everyone can file their design to manufacturing services through universal design standards, and any number scale manufacturing design products, it may also be used to manufacture desktop tools.

There are still some parts of these three points in dispute, such as might exist in the open source community copyright problem, and SHANZHAI issue. On the other hand, 3D printing technology is still facing the price difficulties, it’s not affordable to anyone. This will undoubtedly become to the difficulty for the Makers development. And Anderson discussed in these areas was a bit too optimistic. Of course, perhaps it’s because of the current US manufacturing status – US factories manufacturing reflux return, and these factories are no longer old time factories, it has become an Internet-based factory, the workers of these factories will become an important part of Anderson’s Makers.

There is another big problem of the 3D printing is that lots of Job opportunities will disappear when the 3D printing is developing, especially in the developing country such as China, India and other big manufacturing country. Basically, the 3D print technology is a kind of automation. Therefore, there is no doubt that 3D printing could help the capitalist save a lot of money on employees, because they may just need hire much lesser people than before. However, it’s really a bad news for the traditional industry workers, it’s because it seems like there is no position for them in the future industry. Then the unemployment problem will cause a lot of other social problems.

Although 3D printers in the selection of materials and the molding precision can not match with the traditional manufacturing process, and the scope of application is also limited to a few areas such as the model, toys, and others. However, Anderson convinced that technological progress power: In the 1980s, the printer is noisy, and could only do a simple monochrome printing. Today, we have a cheap, quiet full-color inkjet printer with the resolution even as nice as a professional printer.

3D printing is actually just reduces the difficulty and cost of manufacturing entities, desktop manufacturing tool (also including laser cutting machine, scanner, small CNC machine tools) a single high expectations placed on him is not realistic. These desktop manufacturing tools mainly used to manufacture samples or small-scale production. Slightly larger scale manufacturing requires highly automated manufacturing tools (such as KUKA workshop).

To meet the individual needs is the need for community support, information communication through the Internet will be established enthusiast community, the open source community and faster product updates iteration. These fans are also part of the consumer, they will become their own physical needs. Typical representatives of local motors.

At the same time, we can not deny that in this way the whole community needs to have sufficient cognitive surplus and record customer spirit (do it yourself, while keeping open). This cognitive surplus there may be a potential, we need to find ways to develop it.

Post 6:

Is the maker is the future?

Some science-fiction scene will soon become a reality: you may design according to their preferences to create every piece of furniture at home; you can manufacture your unique toy designed for kids. In 2012, the world’s first 3D printing the studio opened in Japan, took 15 minutes to scan the body shape of the computer, 3D color printer can print out the 3D portrait.

Chris Anderson always gives people surprise. From “The Long Tail” to “Free”, then this “Makers”, I can see his understanding of the Internet is constantly changing, and his theory is more and more mature. From the real to the virtual, and then back to virtual from reality. By the technology, wealth, talent support, the Internet is changing the whole world in constant evolution, and a technological revolution. So, what the future of the world is like?

Anderson gives the answer in his book – who believes the manufacturing, who could have the success at last. Anderson’s logic is very simple when the Internet completes the virtualization of reality, the business development of the internet will come to an end, it must and it will start to develop a lot of other business. More and more internet companies will choose to build a connection on their online and offline products. So we can see Google driver, Google Glass, and other products. But what the more important thing is, compared with traditional manufacturing, the Internet industry is much more powerful and efficient. Examples cited in the book of Citibank: According to Oxford Economics data Citibank institutions, broadly defined digital economy gains of about $ 20 trillion while the total outside of the network economy, according to the same standard estimate of 130 trillions of dollars. The next ten years of the Internet only could find their future by more focus on manufacturing.

To this end, Anderson went to Manchester Britain’s first industrial revolution clues and try to find future proof (the chapter title is “The History of the Future”) in the past. Then he held up “the long tail” theory which made him famous, the long-tailed line extending to the line, extended from the long tail of virtual entities to the long tail, he further illustrated with the representatives of large industrial-scale production technology gradually fading, consumers need the more unique, and more personalized products.

With the market right now, how can we meet consumers’ demand? Here the core of this book Anderson –How to give consumers unique and personalized products. Here three kinds of ideas:

1.Digital desktop tools (such as 3D printing technology) design products

2.Share design results in the open source community, and do more cooperate with other people.

3.Everyone can file their design to manufacturing services through universal design standards, and any number scale manufacturing design products, it may also be used to manufacture desktop tools.

There are still some parts of these three points in dispute, such as might exist in the open source community copyright problem, and SHANZHAI issue. On the other hand, 3D printing technology is still facing the price difficulties, it’s not affordable to anyone. This will undoubtedly become to the difficulty for the Makers development. And Anderson discussed in these areas was a bit too optimistic. Of course, perhaps it’s because of the current US manufacturing status – US factories manufacturing reflux return, and these factories are no longer old time factories, it has become an Internet-based factory, the workers of these factories will become an important part of Anderson’s Makers.

Although 3D printers in the selection of materials and the molding precision can not match with the traditional manufacturing process, and the scope of application is also limited to a few areas such as the model, toys, and others. However, Anderson convinced that technological progress power: In the 1980s, the printer is noisy, and could only do a simple monochrome printing. Today, we have a cheap, quiet full-color inkjet printer with the resolution even as nice as a professional printer.

POST 5:

reflection on Makers:The New Industrial Revolution Chapter 7 Open Hardware by Chris Anderson

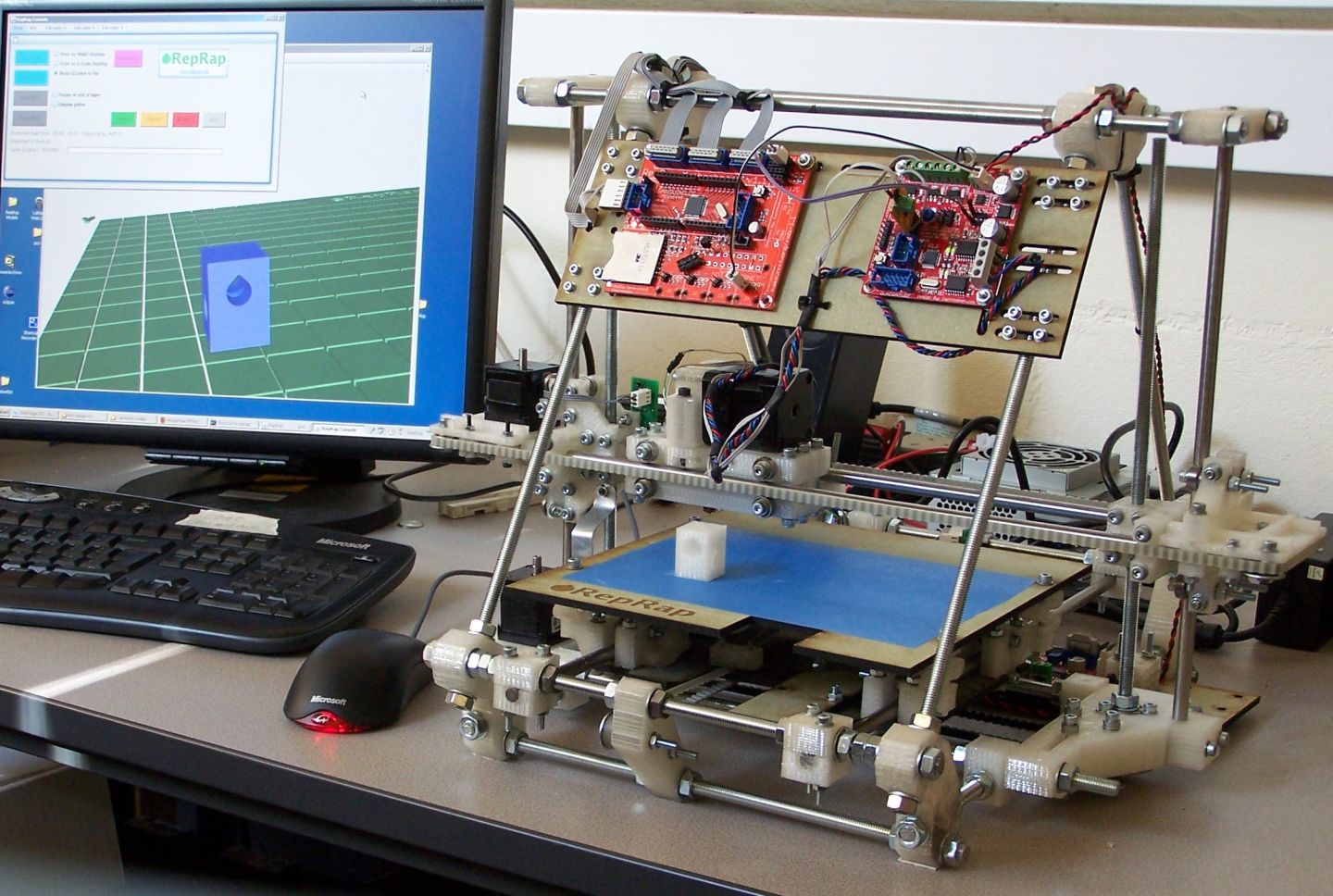

Now, more and more inventors begin to share their invention to public, because they find that it would be helpful on their stuff improvement. They can get a lot of new ideas and inspirations from other people when people working on the same thing in different ways. There are a lot of 3D print model web on internet, and during my project i could see other people how to solve toy car parts problem, and get many useful ideas. From the pages I first know that the 3D printers are also open hardwares, such as MakerBot and RepRap 3D printers.

reflection on the field trip:

First of all I’m really happy to have a chance to visit the makerbot factory. It’s a awesome place inside(but the place is really hard to be find), the guide leaded us visit a lot of place in the factory, it looks unlike the normal factory, people are enjoy their work. It’s so cool because most of their facilities were made(printed)by themselves. Their place looks like the combination of modern office and factory. Light, clean and big, i think people who is working there should not feel bad.

About the last place we visit, i think that place is kind of welfare for artists. That’s why art could be such development in NYC and artists all over the world want to come to NYC, because people could have a nice place with a low price and a lots of intelligence artists around, artists could get inspirations from each others’ project and it’s very helpful for them.

POST4: Phase 1 project inspiration proposal:

Phase 1 project

Assignment#3:

At the beginning, all my knowledge about the 3D printing products is that they can be used as prototype stuff, and that’s it. However, during the NYFW FA2015(New York fashion week), my friends sell some 3D printing shoes to a designer, and it was wore by models walk on the runway. At that time, i finally notice that the 3D printing products is mature, and its product will go into the normal people’s life. It told me that the prospect of 3D printing is very nice.

Because i want to make a toy car at last, so i design a very easy car by tinkercad.

————————————————————————–

Assignment#2:

3D printer test project

Recourses:

1.Ultimaker 2

2.Cura

3.SD card

Challenge & usage:

Forget to get the gcode file at first, so it made me try to find my file for 10 mins.

After the work done, the product could be get out of the platform easily with grab the thin line.

————————————————————————-

Assignment#1 :Process Example: 3D printer Ultimaker 2

Product Comparison:

3D printers

Prusa i3

Replicator 2

RepRap

Form 1+

FlashForge creator pro

Printrbot Simple Metal

XYZ printing

3D printer Structure :(from http://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/processes/)

Stereolithography process(SL): the first 3d printing process

DLP( digital light processing)

Popular models of 3D printer (Ultimaker)

- Ultimaker Original

- Ultimaker Original+

- Ultimaker 2 Go

- Ultimaker 2 Extended+

- Ultimaker 2+

Important terms:

1.Don’t forget to get a gcode file before turn in the SD card if you download the STL file from internet.

2. Shut down the machine after the machine cool down.

3. Don’t forget your SD card after all work done.

others could be find on

https://ultimaker.com/en/tips-tricks/11720-terminology

Usage:

1.make prototype

2.Make products as shoes and this stuff could be used in NYFW(life area)

3.Now 3d printing products has been used in medical science.

[…] Tianyu Ren […]

赞赞